Learn all about anti-vibration at ISMT: methods, applications, materials, costs and practical tips to reduce noise pollution. Find out now!

All about anti-vibration

Noise and vibrations are very annoying. That is why at ISMT we are always looking for the latest developments and technologies that improve living comfort. And anti-vibration is definitely one of them. Did you know that unwanted vibrations and noises are not only annoying, but can also cause damage to machines and buildings, for example? Fortunately, there are numerous solutions on the market today to tackle these problems. Get inspired and read more about anti-vibration and how it can contribute to a safer environment.

What is anti-vibration?

Anti-vibration is a technique used to reduce and even eliminate unwanted vibrations and noises. These vibrations and noises can come from various sources such as machinery, vehicles, buildings or equipment. When these vibrations and noises are uncontrolled, they can cause damage to the environment and equipment. Fortunately, there are various anti-vibration techniques that consist of special materials such as vibration dampers and insulation materials. But there are also techniques for making structural changes to reduce vibrations. This way, you create a safer and more comfortable environment for people and machines.

Reasons for anti-vibration

There are several reasons to apply anti-vibration materials. We have listed them for you:

- Safer working environment: Anti-vibration can contribute to a safer working environment. This is because vibrations and noises can lead to health problems in employees, such as hearing damage and stress.

- Less cost: Vibrations can cause damage to equipment and machinery. This leads to higher maintenance and repair costs and more downtime.

- Increase machine life: Anti-vibration techniques help to increase the lifetime of machines. This saves costs.

- Higher quality products and services: Anti-vibration can contribute to higher quality products and services. By reducing vibrations on a production line, the accuracy and consistency of the products produced can be improved.

- Reduced noise pollution: By applying anti-vibration material, noise pollution is reduced and sound quality increased. So you have less trouble with unwanted environmental noise.

Methods for anti-vibration

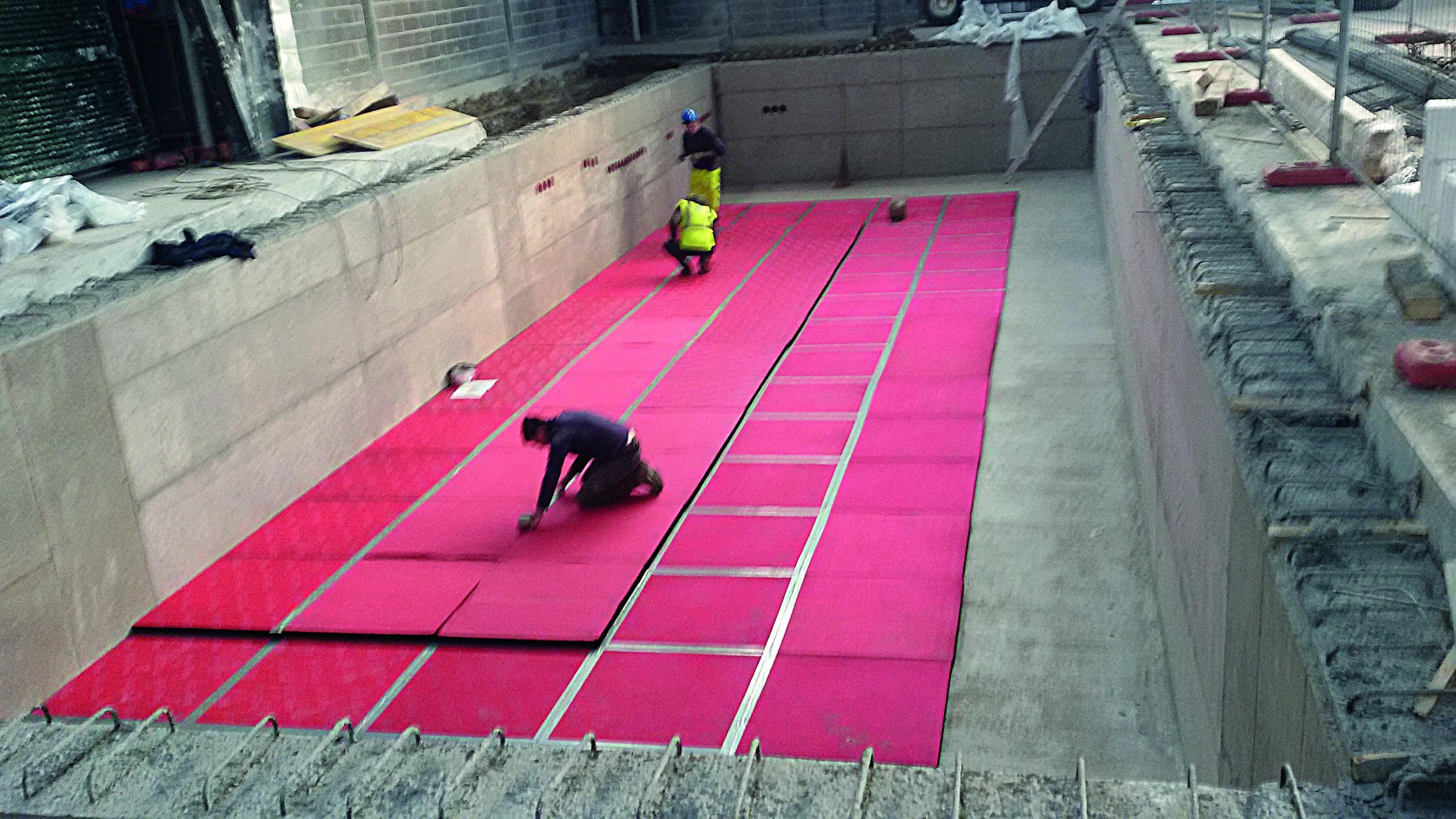

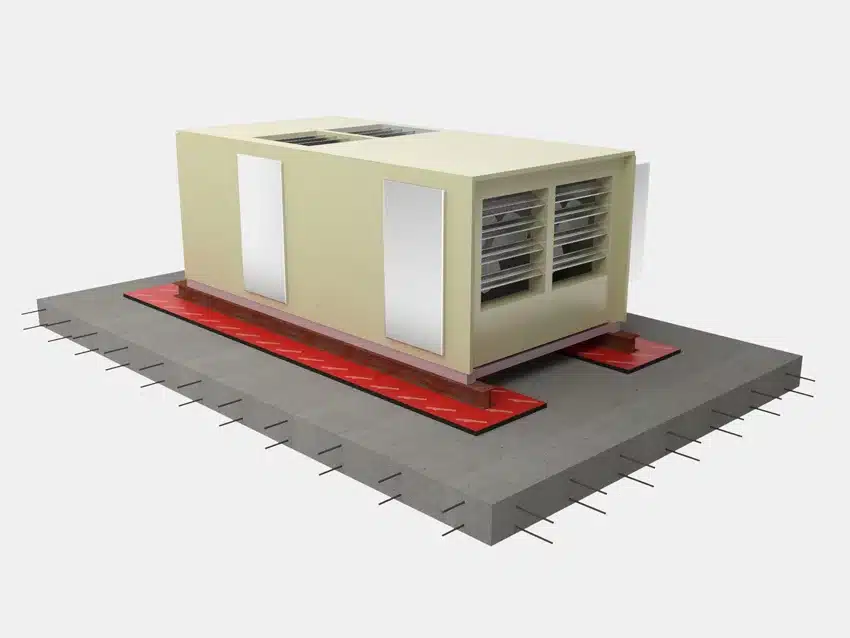

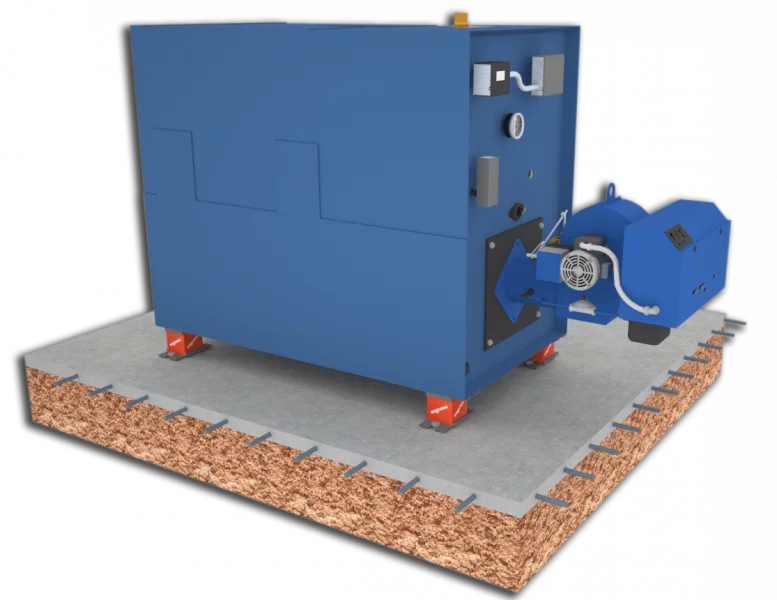

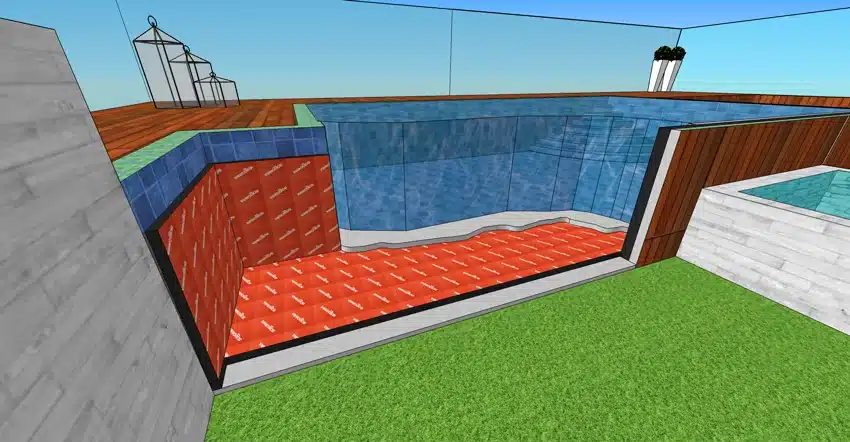

There are several techniques that can be used for anti-vibration. These include anti-vibration mats, anti-vibration plates and anti-vibration materials. You can place vibration dampers between the source of vibration and the surrounding structure. These dampers absorb the energy of the vibrations, reducing them. Another method is to use insulating materials such as rubber and foam. These can be applied to the surfaces where vibrations are caused or absorbed. This reduces the transmission of vibrations to adjacent parts of the structure.

ISMT places particular focus on de-absorbent mats, the Isolgomma Megamat in particular. This Megamat is the ideal solution for controlling internal vibrations produced by machinery. It is also the ideal solution for external vibrations. This is the case, for example, for all companies that need to ensure the proper operation of measuring instruments that are sensitive to vibrations. Isolgomma Megamat is resistant to oils, moderately aggressive acids and is moisture and frost resistant.

Applications of anti-vibration

Soundproofing is an important aspect in the design and production of structures in various industries. In the construction industry, for both residential and non-residential construction, for example, anti-vibration is used to reduce vibrations and noise. In industry, such as mechanical engineering and yacht/shipbuilding, anti-vibration is used to extend the life of equipment and structures and improve performance. This is done by absorbing and reducing vibrations and shocks, among other things. As a result, machinery runs stably. Thanks to the many applications of anti-vibration, structures can be made more durable, efficient and safe, making them better able to withstand the challenges of modern industries.

Materials for noise reduction

When reducing vibrations and noise, choosing the right material is crucial. There are different types of materials used for anti-vibration, each with their properties, advantages and disadvantages. The selection of materials depends on the pressure load of the machine and the frequency range in which improvement is required.

- Soft materials: here are soft materials such as foam rubber and elastomers, which are excellent at absorbing vibrations. Such as Isolgomma’s rubber products.

- Stiffer materials: There are also stiffer materials, such as metals and composites, which are more suitable for isolating vibrations and reducing noise. As a result, the Isolgomma Megamat in particular is used in different versions, depending on the weight of the machine and the frequency range in which improvement is required.

Economic benefits

Besides the technical benefits of anti-vibration, it also offers economic advantages for companies and end users. By reducing vibrations and noise, machine life is extended and the number of repairs is reduced. This reduces downtime and increases productivity, which is cost-saving in the long run. In addition, dethermalisation contributes to a better living environment by reducing noise pollution in homes, offices and public spaces, for example. This ensures a higher quality of life and better well-being for people.

Comparison of anti-vibration techniques

There are several methods of anti-vibration available and it is important to choose the right method in a specific situation. The right method depends on several factors, such as the application, the environment and the weight of the structure. At ISMT, we offer a wide range of de-deroofing techniques such as active de-deroofing, passive anti-vibration and hybrid anti-vibration, each with their own unique features and benefits.

-

Active anti-vibration: Active anti-vibration is suitable for applications where high performance and precision are required. Active anti-vibration is, for example, a spring system, where a counteraction is used beforehand

-

Passive anti-vibration: Passive anti-vibration is ideal for simple applications where cost savings and ease of use are important. Passive anti-vibration is, for example, rubber, such as Isolgomma Megamat.

-

Hybrid anti-vibration: Hybrid anti-vibration combines the advantages of both active and passive anti-vibration, making it suitable for more complex applications.

Future of anti-vibration

Developments in the field of anti-vibration never stand still. In the future, we will see more and more innovative applications of soundproofing, where reducing vibrations and noise will become even more important. Consider, for example, the development of new materials and techniques that can deliver even better performance in environments where vibration and noise are a major problem. Such as in aviation and shipping. There will also be an increased focus on sustainable de-dredging solutions, where reducing energy consumption and minimising environmental impact will be key.

Sustainability anti-vibration

At ISMT, sustainability is important to us, which is why we strive to make our anti-vibration techniques and materials as environmentally friendly as possible. We use sustainable materials and production methods that minimise environmental impact. For example, we have anti-vibration materials made from 90% recycled and reused materials. This also contributes to a more sustainable future. Aware of our responsibility as a company, we also take our role in reducing the environmental impact of our products seriously.

ISMT project support makes it silence in every project

At ISMT, we have extensive experience in anti vibration solutions in buildings. We can guide you through any project and give you reliability at every stage. For each project, we make calculations that we present in a report. This report includes the values according to the Dutch Building Decree and contains an overview of the required materials. We test the pressure load in advance and measure the long-term performance. In addition, we provide optimal guidance and go for the best possible result. We support you with advice and guidance at every stage of the process. Contact us without obligation.

Do you need advice?

Would you like advice, a free sample or documentation

Contact our experts.

Call +31(0)88 0184900 or leave a message via the contact form.

Contact us

Practical tips for anti-vibration

Naturally, you want to reduce noise pollution as quickly as possible. Fortunately, there are a number of practical tips you can apply to achieve this. We have listed a few applications.

-

Anti-vibration mats: One of the most effective ways to reduce noise pollution is to use anti-vibration mats. These mats are specially designed to absorb vibrations and noise pollution and are suitable for a wide range of applications. Including residential, commercial and mechanical engineering. Our Isolgomma Megamat is very suitable for this purpose.

-

Ensure good insulation: Good insulation of walls, ceilings and floors can help reduce noise pollution. Choose materials with a high sound insulation value and make sure there are no holes or gaps for sound to pass through.

-

Reduce vibration: Besides noise, vibration can also cause nuisance. Reduce vibrations by choosing the right anti-vibration material.

-

Choose sound absorbing materials: Using materials with a high sound absorption value such as special ceiling or wall panels will help absorb sound better and keep the room quieter.

-

Install acoustic panels: Acoustic panels are specially designed to absorb and reduce sound. They can be used in spaces such as meeting rooms and offices, as well as in residential homes.