High quality

Quick service

High knowledge

Sustainable products

ISMT SINCE 1972

How it all started

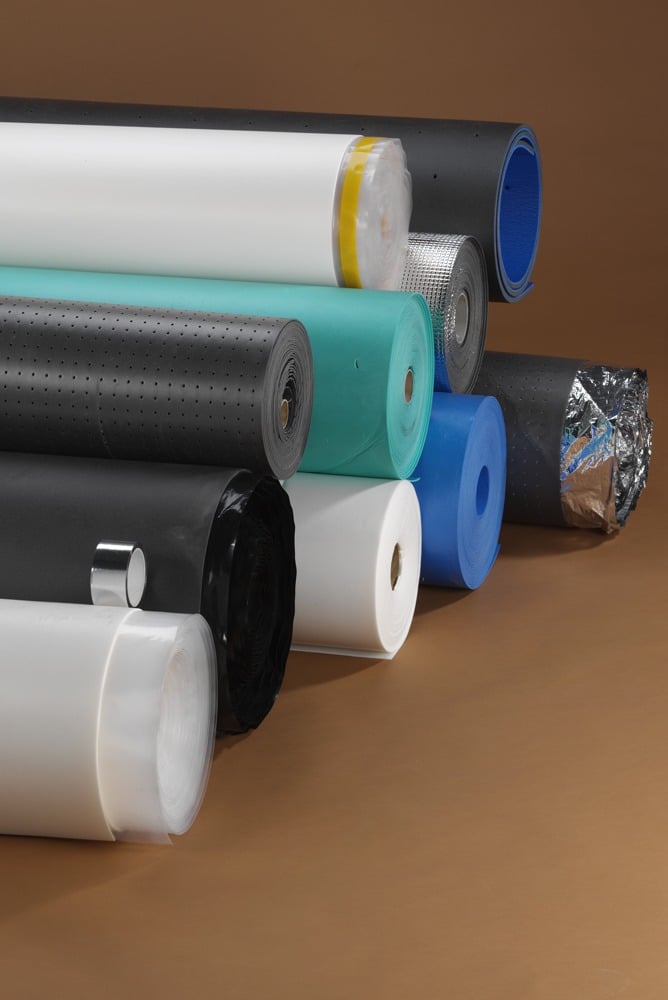

Due to increasing demand for PE tape as seals, the independent business unit Imbema Kunststofchemie B.V. was founded and started at Wilsonsplein in Haarlem. In the same year, one of the first applications was started; self-adhesive PE tape. In this, a partnership was formed with Alveo to process the PE foams they produce into various applications.

1973

Establishment of Imbema Kunststoffchemie GmbH

A year after establishment in the Netherlands, a subsidiary in Germany is also opened.

1975

International registration of brand name SIREX

In 1975, SIREX was registered in the Benelux as our own brand. After more and more customers arose outside these borders, the brand name was also registered internationally in 1976. This was the start of a wide range of our own products in, a.o. the sports and leisure, construction and industrial markets.

Quality in our DNA.

Origin of camping mats

Having sold PE tape for several years, we came into contact with outdoor shops where there was interest in insulating sheets of 200x50x1 cm. These were used as insulation under sleeping bags. This is how the SIREX camping mats came into existence. This created additional volume for the machines for PE foam production.

Eighties

Eighties

Development of swimming pool covers

The first type of SIREX pool cover was developed in the 1980s. Today still a quality product of ISMT. SIREX Pool Cover ensures that heat is retained in the pool and there is also less evaporation of chlorine. When used outdoors, it also prevents leaves and dirt from entering the pool.

The ’90s

1993

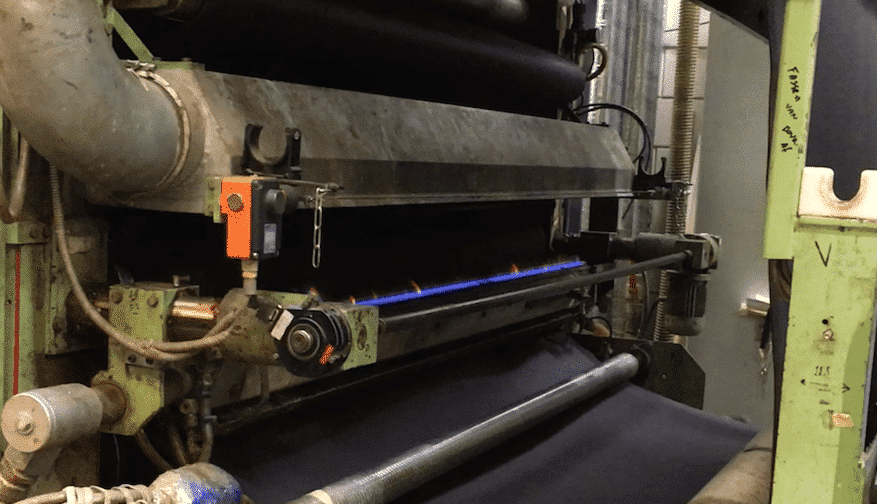

Investment in (flame) laminating machine

In 1993, a flame laminating machine is acquired. This allows several layers of foam to be put on top of each other, but also combinations of PE with textiles, foils, synthetic leather, etc. are possible. The advantage of flame lamination is that no adhesives are added and the adhesion is very strong.

1993

PE sleeping mats for specific uses

As specialists in the production of our SIREX PE sleeping mats, we are asked more and more regularly by various defences and NATO to help develop the right PE sleeping mat. There is also a growing demand for special sleeping mats for a.o. mountain expeditions.

1996

SIREX laminated floor underlays

An extension to the range is SIREX floor underlays. These PE underlays are flame laminated with a vapour retardant PE foil. This makes it much easier to lay the underfloor instead of two separate layers.

1997

Thermoforming production

Thermoforming is a fairly new technique in 1997 that we have used as an innovation for various custom-made products. One of the first thermoforming products were knee pads.

1998

SIREX STAR gymnastics mats

With the experience gained in thermoforming products, the SIREX STAR gymnastics mat was developed in 1998. These gymnastics mats are of very high quality and have a long lifetime. A product that is still produced by ISMT today.

1999

Development of SIREX Casco foam

In semi-detached houses, a problem in horizontal sound transmission arose because the floors were being cast together. To interrupt this, SIREX Casco foam was developed. Its flexible properties made it easy to process. This product was also flame laminated and reduced a lot of impact noise.

2001

SIREX STAR plus technology

An addition to the thermoform range is the Plus technique. This strengthens the surface and provides a more scratch-resistant material, ideal for the application of a.o. therapy mats.

2002

Partnership with Zotefoams

Zotefoams’ products will be added as an extension to the already broad PE foam range. With this partnership, we will have access to even more specific application possibilities demanded in the market.

2008

Expansion of building programme with Isolgomma acoustic insulation

The demand for acoustic solutions is increasing in the market. This is why we decided to expand our programme with Isolgomma’s products.

2011

Organisation of acoustic seminars

In addition to our acoustic programme, we will begin to organise seminars in 2011. In these seminars, we shared our knowledge and experience to ensure that quieter buildings can be created.

2013

Isolgomma Grei is used in supermarket floors for the first time

After many reports and in house testing at Isolgomma, Plus Overloon is the first supermarket to apply Isolgomma Grei under the screed. This project was measured in practice by M+P and exceeded acoustic and pressure load requirements. After this project, many other shop/supermarket projects will follow.

2014

Applying acoustic insulation under tiled floors in renovation of supermarkets

During renovations, tile upon tile was always glued. The refurbishment of C1000 to Plus in Arnhem is the first project where Isolgomma Sylcer was glued under the new tiled floor. The result was so good that it became the standard for Jumbo during refurbishment/reconstruction. After this, many other retail chains will follow Jumbo’s example.

2015

Isolgomma Grei and Upgrei are applied in transformation projects

Until now, mineral wool and EPS have mainly been used in renovation/transformation. This includes first-fill layers to reinforce flexible floors. Isolgomma’s thin insulation saves height and weight and demonstrates through onsite testing that it meets all requirements.

2015

Name change from Imbema Kunststofchemie to Imbema SMT

Over the years, our company has evolved into an expert in a broad spectrum of all kinds of synthetic materials. It is therefore time to give our company a name to match: Imbema Synthetic Materials Technology

Why this name?

Synthetic Materials is a broad base for our company, for now and in the future. Technology fits well with the vision and knowledge level of our employees, as well as many of our products.

2017

New (flame) laminating machine

After almost 25 years of faithful service, the flame laminator is being replaced and expanded. The new machine offers even more possibilities and with this, we are ready for the future.

2018

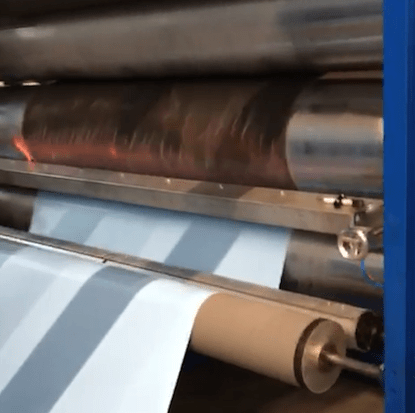

Purchase of new splitting machine

To respond quickly to market demand, we split in-house. We cut slabs from sheets or blocks at a maximum width of 140 cm and at a thickness of 1 mm to 130 mm.

With the splitting machine, we cut rubbers and foams (hard and soft) almost instantly to any desired thickness.

2020

Launch of ISMT, independent from Imbema group

The current management team Jeroen Dechering, Jamie de Boer and Albert Jansen, has acquired 100% of the shares of Imbema SMT B.V. including the German subsidiary Kunststoffchemie GmbH and will continue under the name ISMT.

Start of waste take-back recycling program

2021

2022

Move into new office and warehouse in the Netherlands and office in Germany

After a long time of preparation, the time has come to move and take up residence in a new office and warehouse in the Netherlands. This location at Küppersweg 18 in Haarlem is equipped with the most up-to-date facilities such as extra insulation, LED lighting, underfloor heating, skylights in the warehouse and loading docks. We are also moving into our new office in Germany at Ludwig-Herr-Strasse 23 in Kornwestheim. All in all, this will ensure that we are ready for the future.