The right foam choice for safe industrial packaging

Choosing the right type of foam for secure packaging is very important to effectively protect products during transport and storage from bumps, impacts and other potential damage. When choosing the right foam, you need to consider several factors such as the specific application of the product and the required properties. Moreover, weight, dimensions and quantity also play a role. Read more about the right foam choice for packaging material.

Why is it important to choose the right type of foam?

Choosing the right type of foam is important because of the essential role it plays in protecting products during transportation and storage. Using the right foam protection can lead to good protection against impacts, shocks and other external influences. This keeps products better protected and reduces the need for replacement.

Factors to consider when selecting foam

Which packaging foam will be used depends on a number of factors. These include:

- Protection against impact and shock

- Weight and density

- Compression properties

- Chemical compatibility

- Open or closed cell structure

Do you need to pack a large, heavy machine or do you need an inlay for a toolbox? Depending on the application, we consider whether hard or soft foam is needed. This will help determine the right density of foam for the application. Is it also necessary for the packaging to look aesthetically pleasing? This is all taken into account. It is also important to consider the specific requirements of the material. Does the foam choice need to be flame-retardant, anti-static or conductive? These are also factors to consider when choosing the right foam protection. At ISMT, we specialise in safe industrial packaging. Whatever product needs to be packaged, we know which packaging material you need within various industries.

Different types of foam packaging

There are several types of foam packaging that can be used as packaging materials. Each has unique properties and suits a range of products.

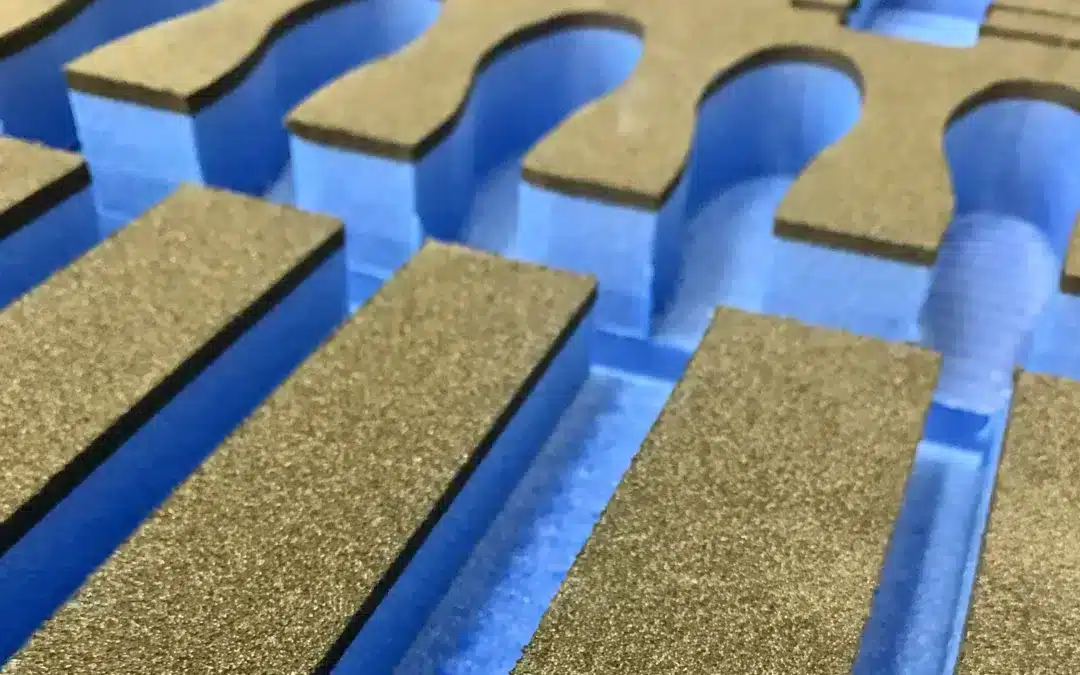

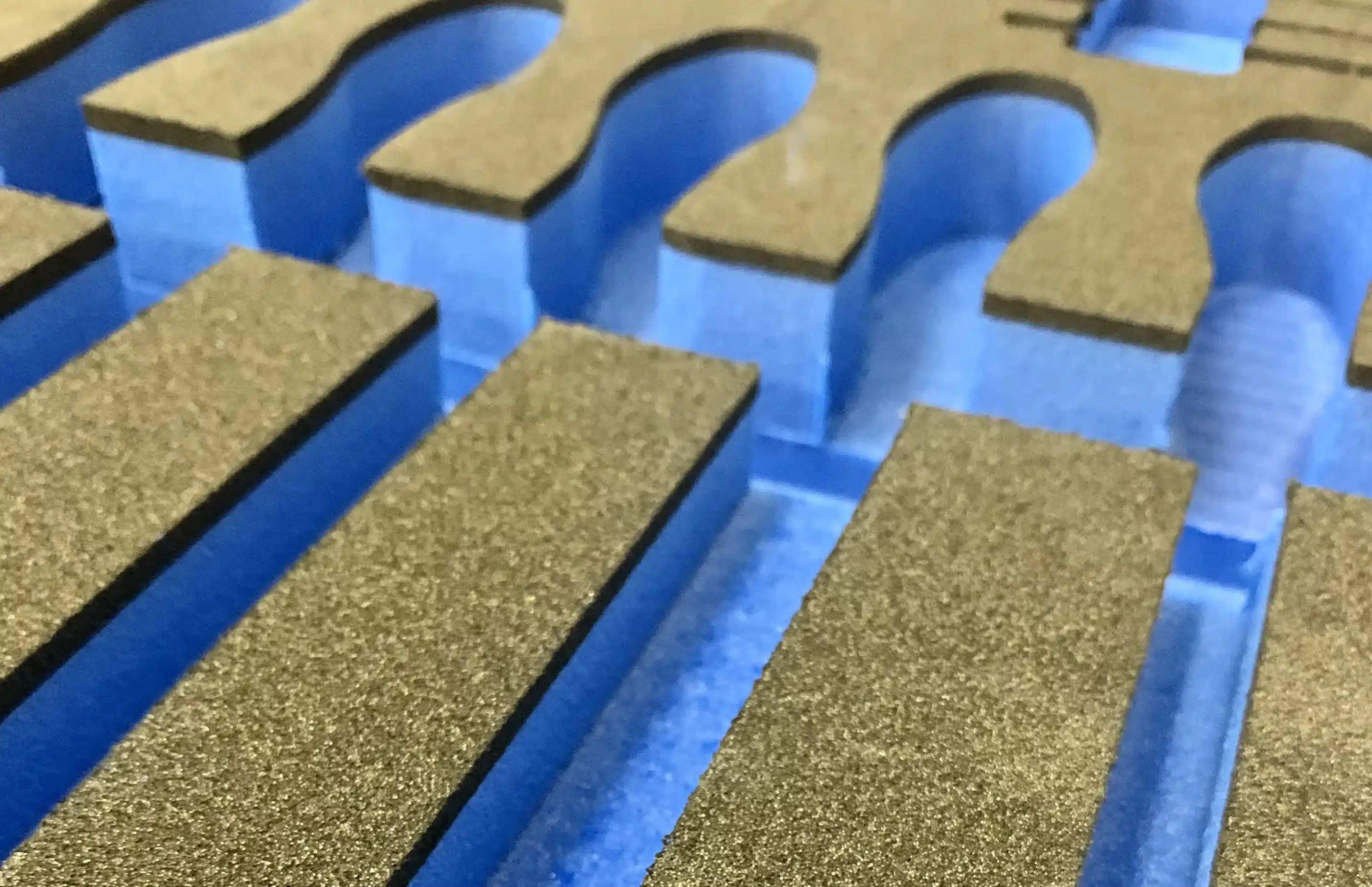

- Polyethylene foam (PE foam): PE foam has a closed-cell structure and can be used both in cross-linked form for high-end applications and in non-cross-linked form for more affordable solutions such as buffers in television packaging.

- Polyurethane foam (PU foam): PU foam has an open-cell structure and is available in several variations, such as polyester, which is widely used in various industries for different applications, including inlays for suitcases and picking foams. And polyether, which is widely used for mattresses, cushions, but also as a cost-effective solution for packaging.

- Ethylene-vinyl acetate foam (EVA foam): EVA foam is a flexible material that is much more elastic, shock-absorbent, abrasion-resistant and durable compared to PE foam. It is often used in high-quality industrial packaging and insulating mats.

- Polystyrene foam (EPS foam): Polystyrene, also known as Styrofoam, is a widely used foam for (disposable) packaging, horticulture and technical industries, due to its relatively low cost.

When choosing the right foam packaging, it is important to consider the required quality standard. Are there specific requirements on tolerances, materials and desired delivery date? Perhaps the packaging needs to be waterproof. Quality requirements are also important when it comes to medical applications. We can therefore also process products cleanly. This allows our customers in the medical industry to use or process the products immediately, without having to clean them thoroughly first. In addition, products are well protected against oil leaks or chemicals. The product will not be affected.

ISMT is ready to advise you on the different types of foams, so that you make the right choice and select the most suitable foam for your specific packaging needs. We help you from A to Z. No matter how specific your requirements are.

Frequently asked questions:

How can I determine the density of foam?

The density of the foam depends on the application. Heavier products generally use a higher density foam.

Can I reuse foam?

This depends on the type of foam. In general, you can reuse high-quality foam. It also depends on the purpose. A foam interior in a toolbox has to be used frequently. Therefore the foam must be suitable for this purpose, which is why we recommend, among others, our SIREX BLOCK foams for this application.

Is foam packaging environmentally friendly?

Depending on the type of foam, packaging can be environmentally friendly. During foam processing waste foam can be left over. This can be reused again for the next product. Virgin PE foam can be recycled into basic blocks, consisting of flakes thermally compressed together. In addition, PU foam can be cut into flakes, from which recycled boards can be produced again.

Do you need advice?

Would you like advice, a free sample or documentation

Contact our experts.

Call +31(0)88 0184900 or leave a message via the contact form.

Contact us